What to Look For When Choosing the Ideal Cable

Picking a good cable is essential for any home device if you want it to work optimally, so you can only imagine how important using the right cable is in industrial settings where the cables are responsible for powering machines that have strict requirements and cost millions of dollars. Each and every cable powering industrial equipment should be chosen to suit the application and the environment in which the cable is located, because most of the time, industrial settings are rough. With that said, there are a couple of careful considerations you have to make when buying industrial cables, including the cables’ construction, their shielding, and operation.

Cable Construction

The construction of a cable involves conductors, insulation, arrangement and finish covering. The conductors are usually either aluminium or copper. When picking, consider the environmental conditions, workmanship and the required maintenance. The requirements for aluminium conductors in regard to these factors are more important than the ones for copper conductors.

Cable Arrangement

Conductors are arranged to form a three-conductor cable or a single-conductor cable. Both types have their distinct advantages and disadvantages. Single conductor cables are easier to splice, install and allow you to form multiple-cable circuits. However, they have higher reactance than three-conductor models, and shielded single conductor cables carry high shield currents which can overheat them.

Another important consideration is the availability of a ground wire in three conductor cables versus a separate ground wire with single conductor cables. The ground conductor in three conductor cables provides a lower independence path and offers a good system ground.

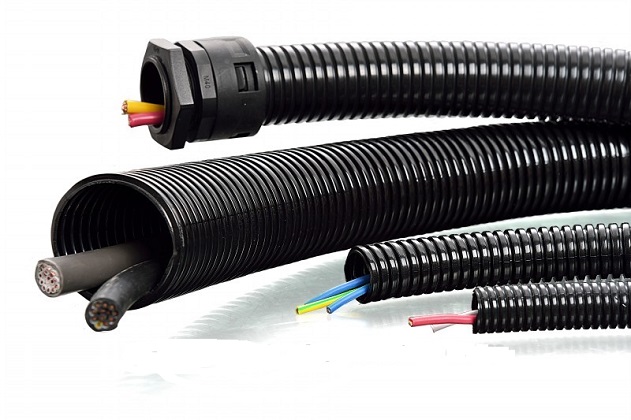

Finish Covering and Insulation

The selection of the finish covering and insulation is usually based on the service conditions, type of installation, ambient operating temperature, type of load served and other criteria. For instance, in situations where the cable will be susceptible to bending, you’ll need a flexible conduit, while in other situations, you’ll need a cable that’s resistant to high ambient temperature, insects and rodents, oil and solvents, etc. The flexibility of the flexible conduit and the resistance of the cables can vary greatly, so you should pick according to how much you need of which property.

Cable Operation

The cable’s insulation has to be good enough to withstand the stress experienced during abnormal, as well as normal operating conditions. That being said, the selection of the insulation should be based on the applicable phase-to-phase voltage and the general system category. The general system categories are classified as either 173%, 133% or 100% insulation levels.

Shielding

Cables can either be shielded or non-shielded. Shielded cables reduce electromagnetic radiation and reduce electrical noise. Moreover, they keep the signal steady and eliminate interference with other devices. There are many different levels of shielding, including FTP, SSTP, and STP. Non-shielded cables, on the other hand, are specifically designed to reduce electromagnetic interference and they’re more suitable for network cabling systems. Additionally, they’re more flexible, thin, lightweight, versatile and affordable.