Vibrating Screen- The ideal Machine For Screening And Grading

The vibrating screen is a large heavy-duty machine which is used to separate liquid, powder and other solid materials. This machine is heavily used in many industry sectors like construction, mining, and chemical. The vibrating screen is also used for grading and screening different kinds of materials in other fields like mineral processing, quarry, water conservancy etc. Generally, the vibrating screen is used to separate gravel and clay, or large and small stones. It is also known as vibrating separator and vibrating screen classifier. By using the power of gravity and with powerful mesh screens, the vibrating screen is a machine capable to complete the work in a fraction of time for which several people are required.

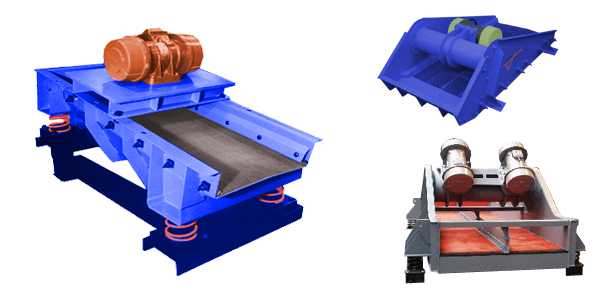

The body of the vibrating screen is consisted of supportive structure and a base frame. The supporting structure and the base frame are made of highly resistant steel. The main parts of the vibrating screen are: eccentric block, rub spring, screen web, coupler, and electric motor. The amplitude can be adjusted by the eccentric shaft and eccentric blocks. In order to screen the materials, the body of the vibrating screen moves in a circle. The main features of the vibrating screen are:

- Simple and efficient eccentric system

- High screening capability

- Durability

- No transmission of the screen panels

- Easy changing screen panels

- Highly resistant and rigid screen body

A vibrating screen operates in a quite simple way. The items that need to be separated are placed on the top layer of the screen. As the name suggests, the whole machine vibrates gently in a circular motion in order to move the materials through the screens and to remove any impurities. This way, the materials move through several layers of screens which have big and small openings. Usually, the large openings are at the top layer, while at the bottom the screens have smaller openings. The end result of the process is sorted materials by size. Any dirt or extra material is being thrown away from the vibrating screen. As said above, the amplitude of the vibrations can be adjusted in order delicate and specific materials to be effectively separated.

The mining sector is the biggest user of vibrating screens. The ores and the minerals which are extracted from the ground come with many impurities. Because of that, the miners rely heavily on using a vibrating screen in their daily tasks. Furthermore, the screens are also utilized in the construction sector, especially when screws and ionized bolts need to be cleaned in water and then dried. A container full of water and metal items can be poured through the vibrating screen so that the screws and bolts can be separated and dried efficiently.