Shaft Power Meter: What Makes It Ideal

The instrument that allows the computation of propeller output power by the measurement of shaft torque and shaft rotational speed is called shaft power meter. Normally, it is installed on ships as to attain output power control.

Shaft power meter has a high value system that is incorporated into large sized ships during construction. To determine the torque in the propeller shaft you need to grade the surface strain in that shaft using strain gauges fitted inside. The strain that you gain is caused by twisting the shaft, because of the torque forces inside of it and the fact that it is proportional to it. The speed of rotation is measured via a magnetic pickup and a toothed ring fitted near the shaft which generates a pulse train whose frequency is proportional to the rotational speed of the shaft. Currently, shaft power meter use a PC and data acquisition system as to preform this task in the most accurate way.

Shaft power meter equipment is composed of:

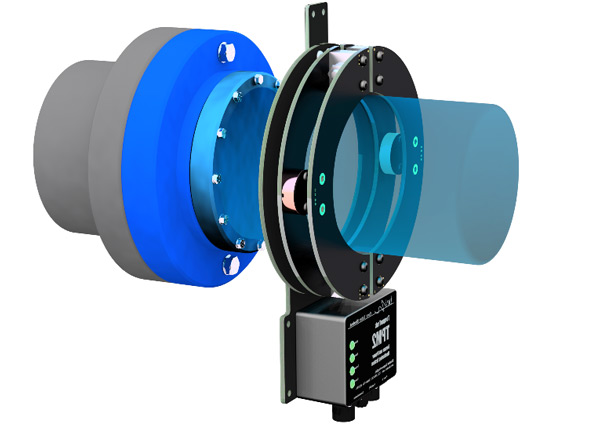

Rotor Unit: The torque is calculated by using strain gauges secured to the propeller shaft. The signal that comes is amplified and converted to a frequency signal. With multi-turn potentiometers, you can adjust the span and the offset ranges of the signal. The signal is then used to amplify and modulate an RF carrier signal which is to be delivered to a loo aerial. This design uses a couple of analogue components.

Stator Unit: This unit provides the demodulation of the torque signal, which is done inside the primary coil, together with the power drivers. Shaft speed is measured by the magnetic sensors of the stator unit, activated by a ring of teeth cut in the metal of the rotor unit.

Data Signal Processing unit: This unit is composed of PC parts and Commercial data acquisition card. The process of Data acquisition converts the analogue input to digital format, transfers it via a compatible interface to the PC for computation. The data is then fed via another port and it is displayed on the screen.

With the introduction of the micro-controlling component inside the Shaft power meter, the complexity of the overall system has been reduced and simplified, leading to reduced cost and less manufacturing time. Additionally, the simplified setting reduces the commissioning costs and improves facilities departments to reduce their maintenance cost.

The adoption of microcontroller technology led to a much wider implementation of the shaft power technology in the final product than what was initially envisaged.

Shaft power meters from 99 are making power inputs safer and controlled. With the complex system and the new technology that is expected to surface in near future, we can be sure that it will thrive and lead us in new directions of draft shaft engineering.