3D Printers: Ideal Technology That Comes in Many Types

Gone are the days when 3D printing could only be seen on TV screens. In fact, 3D printing has been present on the market since the early 80’s when engineers and scientists were the only ones who had access to it. Thanks to the constant development of 3D printing technology, these days both businesses and consumers can enjoy in the large selection of 3D printers. The key is to understand the types in order to find the one for your needs.

Stereolithography (SLA)

SLA is one of the oldest types of 3D printing and it’s used for 3D printing of items. Whether you are someone who wants to print a plastic prototype of his upcoming project or an engineer, stereolithography can revive your project. The operation of these printers is simple, they operate with an excess of liquid plastic that hardens and forms a solid object. Once the plastic is hard, the printer drops down and the laser forms another finishing layer. After that, the product should be rinsed with the help of a solvent and after that placed in an ultraviolet oven in order to complete the process. The quality of the product mainly depends on the printer’s quality, and regarding the printing time, small objects can be printed within 6 – 8 hours using a basic 3D printer, while larger objects can be printed within several days (depending on the size).

Digital Light Processing (DLP)

Developed by Larry Hornbeck, the DLP technology was introduced to the market back in 1987. This technology became pretty popular for its projectors production and it works by using digital micromirrors that are laid out on a semiconductor chip. Although both SLA and DLP printers work with photopolymers, DLP 3D printers need an additional source of lighting. These printers also have an LCD (liquid crystal display) that is applied to the entire surface of the printed layer. Just like SLA, DLP 3D printing machines for sale use a liquid plastic resin, but the DLP one hardens faster thanks to the printer’s bright light. Another reason why consumers and businesses decide to buy digital 3D printing machines for sale is that the printing speed is extremely fast when compared to some other types of printers. Regarding the printing options, digital 3D printers can print almost anything you want, and are popular as they can print even complex and detailed objects.

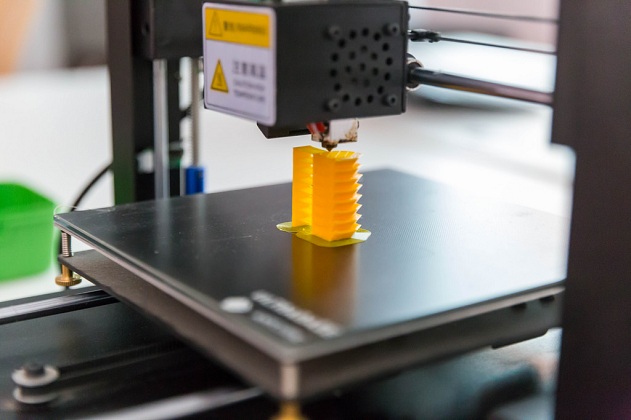

Fused Deposition Modeling (FDM)

Another popular type of 3D printing is the FDM technology which was developed by Scott Crump. The best thing about is that with this FDM technology one can go in high performance and it uses production-grade thermoplastic which is beneficial for mechanic engineers. Thanks to this, FDM is considered to be the only 3D printing technology that can print items which have great mechanical, thermal and chemical attributes. The whole printing time depends on the product’s size and complexity. Nowadays, FDM 3D printing machines for sale are used in automobile, food and toy industries as it allows printing of pretty complex cavities and geometrical forms.

Selective Laser Sintering (SLS)

As the name implies, selective laser sintering is a printing technology that uses a laser as a power supply to form a strong 3D printed object. It was developed by Carl Deckard and it differs from the other types in its use of powdered material. Nylon, glass, ceramics, steel, silver and aluminium are just some of the many materials used for SLS printing which is some of the many reasons why manufacturers use it more than amateurs at home.